Artificial intelligence (AI) isn’t a novel concept. Its origins trace back to 1956 when the discipline was co-founded by John McCarthy, often referred to as the ‘father of AI’. However, it has recently garnered significant attention from the public, particularly following the introduction of OpenAI’s generative AI platform, Chat GPT, in November 2022.

In recent months, AI has been prominently featured in global news headlines, with businesses across various sectors actively exploring ways to integrate AI into their operations. As a manufacturer, you’re likely contemplating the potential impact AI could have on your production lines.

In this blog post, we will delve into potential applications of AI in the manufacturing industry, offer guidance on how to initiate AI adoption, and examine the pivotal role of data in the successful implementation of any AI initiative.

What is artificial intelligence? Artificial intelligence (AI) refers to the utilization of computer software to enable machines to emulate human intelligence, encompassing functions such as vision, speech recognition, and data interpretation to facilitate problem-solving. It serves as a broad category encompassing various methodologies, including robotics, image analysis, language processing, machine learning, and artificial neural networks.

At its core, AI systems employ algorithms to analyse data and recognise patterns. More advanced iterations can learn from experiences, address complex problems, and make decisions autonomously, without human intervention.

Presently, AI applications are prevalent across diverse industries:

Food and beverages: The Campbell Soup Company employs AI to analyse consumer preference data and agile design methodologies, expediting the development of new products.

Waste and recovery: Greyparrot, an AI-driven waste analytics company, has developed computer vision systems for waste identification at materials recovery facilities.

Coding and marking: At Domino, AI is integrated into aspects of targeting values for new formulations and automating testing processes, thereby accelerating the ink development process.

How is AI used in the manufacturing industry?

How is AI utilised in the manufacturing sector?

There are three primary areas where AI demonstrates its value within the manufacturing industry:

- Error reduction: AI systems are adept at comprehending and analysing various forms of visual data, including data from quality control systems along production lines. By identifying patterns indicative of broader production issues, AI facilitates the reduction of waste and errors.

- Predictive maintenance: By leveraging data from maintenance logs and the performance of production lines, AI can forecast machinery performance and anticipate when maintenance or parts replacement will be necessary.

- Forecasting: AI systems equipped with comprehensive datasets encompassing plant operations, production performance, sales, and feedback can forecast demand. This enables manufacturers to optimise inventory management and pre-plan production runs efficiently.

AI in the manufacturing industry

Beginning your journey with AI in the manufacturing sector

Initiating AI integration in manufacturing necessitates meticulous preparation and robust data collection processes across all relevant production activities. Here’s a structured approach to kickstarting the AI journey in manufacturing:

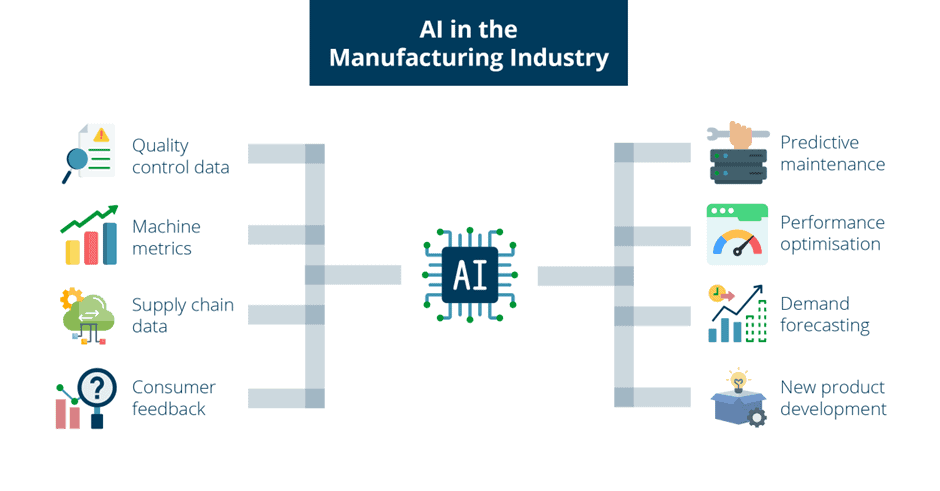

- Quality control data: Implement machine vision systems, such as Domino’s R-Series, to facilitate consistent data collection for training AI models. These systems not only aid in data collection but can also serve as visual input sources for AI analysis and decision-making, enhancing the efficiency of quality control processes.

- Machine metrics: Invest in advanced monitoring solutions like the Domino Cloud to gather insights into machine performance and diagnostics. Historical data gleaned from these systems can be utilised to train AI models, while real-time machine data enables predictive maintenance through AI algorithms, forecasting maintenance needs accurately.

- Production data integration: Integrate production machinery to collect comprehensive data from the entire production line. This aggregated dataset supports AI deployment across performance optimisation, predictive maintenance, and demand forecasting. Domino’s cutting-edge technologies are engineered for seamless integration within manufacturing lines, ensuring smooth communication between SCADA systems and production components.

By laying a solid foundation for data collection and integration, manufacturers can effectively harness AI to drive efficiency, enhance quality control, and optimise production processes in the manufacturing industry.

Upstream and downstream data: Employing variable data coding at the batch or item level, in conjunction with other production monitoring systems as highlighted earlier, enables the correlation of individual products with their production line origins. By incorporating a serialized product code, products can be traced back to their production source, aiding in identifying and rectifying issues should they arise during distribution or end-use.

The significance of variable data coding extends beyond the factory floor as products traverse the broader supply chain and reach consumers. A scannable code featuring a unique serial number facilitates the collection of customer feedback, linking it to the product’s distinct production history. This not only assists in pinpointing issues but also empowers brands to gather valuable data on consumer preferences and trends, aiding in product development and refinement.

Accumulating this information throughout the production process and beyond the factory gates constitutes an integral aspect of a comprehensive toolkit for businesses seeking to fortify their data infrastructure to explore AI applications.

Data forms the cornerstone of any AI endeavour, representing a pivotal initial step in the journey. Without robust data, any subsequent attempts at AI implementation are destined to falter.

Preparing for an AI initiative in manufacturing entails allocating sufficient resources to implement new systems, develop datasets, train AI models, and monitor and analyse progress effectively.

Although discussions surrounding AI often raise concerns about the potential short-term displacement of human workers, the reality is quite the opposite. According to Forbes, AI empowers workers to concentrate on more meaningful and high-value tasks. Moreover, research from both MIT and Statista suggests that human-robot collaborations, which can be up to 85% more productive than teams comprising solely humans or robots, represent the future of manufacturing.

Preparing the workforce for AI adoption is an ongoing endeavour. As technologies continue to evolve, businesses must invest in learning and development initiatives to ensure that employees remain equipped with the requisite skills to adapt and progress alongside AI advancements.

Commence your data journey today

The potential impact of AI on manufacturing is significant, yet success isn’t guaranteed without a strategic plan that prioritizes reliable data collection methods.

Manufacturers are encouraged to engage with existing solutions providers to assess available data and identify solutions that support seamless data collection.

For further insights into Codico solutions for smart manufacturing and variable data coding, we invite you to visit our blog.