Manufacturing and Coding for Face Masks

Terms like face coverings, surgical masks, cloth face masks, community-made masks, medical-grade face masks, and respirators have become commonplace in our daily vocabulary, all with a common purpose: to slow down and prevent the spread of the coronavirus.

The demand for face masks that offer protection against COVID-19 has surged during the pandemic, making it challenging for manufacturers to keep up. The high demand is expected to persist in the long term, given the significant shift in health awareness brought about by the pandemic. Many companies are now grappling with major challenges and adapting to new circumstances, exploring new opportunities.

For some, this presents a chance for transformation and meeting the growing demand. Companies that may have operated in different sectors are now venturing into the production of medical-grade face masks to capitalize on the market growth in this domain. However, manufacturing and coding for face masks involve various considerations, and mishandling these factors could jeopardize plans for market availability.

So, what crucial aspects need to be considered in terms of legal coding requirements when manufacturing face masks?

Face coverings, medical-grade face masks, respirators—how are they different?

To determine the applicable legal requirements for coding and bringing face masks to the market, it’s essential to clearly define the type of product you intend to manufacture.

Differentiations are made among:

Face coverings (community-made masks)

Face coverings encompass home-sewn, reusable masks designed to hinder virus spread, reducing the risk of transmission. They primarily protect others by preventing droplets from reaching them and are intended for private, everyday use. It’s important to note that these masks do not offer a protective barrier and should not be promoted as protective face masks. As such, they are not subject to any coding requirements.

High-quality face masks (surgical masks)

High-quality face masks encompass the well-known surgical masks predominantly utilized in hospitals and medical practices. Their primary purpose is to shield others by obstructing the dispersion of droplets from the wearer’s mouth and nose. The key feature is their ability to safeguard the patient and individuals in proximity to the wearer. These high-quality face masks fall under the category of Class 1 medical devices and consequently adhere to the regulations outlined in the EU Medical Device Regulation 2017/745 (MDR).

Respirators (particle-filtering half masks and FFP masks)

Particle-filtering half masks and FFP masks are predominantly employed to safeguard the wearer by filtering out hazardous substances and viruses from the air they inhale. The level of protection varies depending on the respiratory filter utilized, and certain respirators can offer protection to both the wearer and those in close proximity. These masks fall into categories FFP1, FFP2, or FFP3 based on their filter performance. As a type of personal protective equipment (PPE), respirators are subject to the legal stipulations outlined in the EU PPE Regulation 2016/425.

Coding Requirements for Respirators

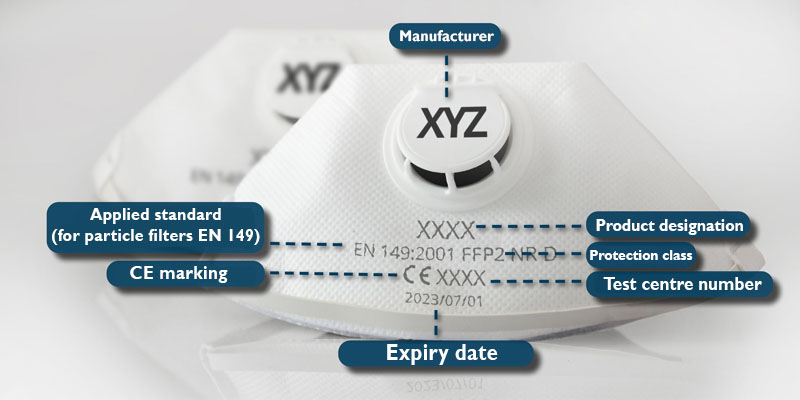

In the production of particle-filtering half masks, commonly referred to as FFP masks, it is essential to adhere to the stipulations of the EU PPE Regulation (2016/425) and the particle filter standard EN 149. Classified as personal protective equipment, these masks offer varying degrees of protection for both the wearer and those in close proximity, contingent on the specific filter used. In regions like the UK and the USA, this type of mask is synonymous with N95 masks, denoting their capacity to filter out a minimum of 95% of tested microparticles.

These masks should be marked with the following information in a permanent, easily readable, and visible manner:

- Manufacturer’s name

- Product designation

- Applied standard

- Protection class (FFP1, FFP2, FFP3)

- Indication of reusability (R) or for single-use (NR = Non-Reusable)

- For reusable respirators, dolomite dust testing is mandatory, and an additional ‘D’ must be included in the marking.

- For non-reusable masks, this test and additional coding are optional.

- CE marking with the corresponding test centre number

- Expiry date

Key considerations for manufacturing and coding respirators

Respirators must undergo a type test as per the relevant standard, carried out by an accredited testing and certification center. Additionally, a conformity declaration needs to be prepared in accordance with the applicable standards. If your aim is to market FFP masks as medical devices regulated by the PPE Regulation, the respirators will also be subject to the Medical Device Regulation.