Optimise the coding process on your extrusion lines

As a partner of Domino, Codico is well-positioned to assist you in discovering an innovative coding and marking solution that not only benefits your business but also addresses challenges such as coding onto extruded products, ensuring a seamless integration of coding and marking into your production environment.

-

Comprehensive Range of Compliant Inks

Selecting inks that adhere well and comply with industry standards can pose challenges in extrusion applications. Codico can provide guidance on the most suitable ink for your requirements while ensuring compliance with industry regulations. This may involve recommending MEK-free, fast-drying, and highly-pigmented options, as well as specialized inks tailored for cable marking. In certain instances, Domino’s inks have demonstrated effectiveness in eliminating the need for pre or post-treatment, leading to significant cost reductions.

-

Swift Coding Speeds and Flexibility

Our coding technologies not only boast impressive speed but also provide the flexibility to design and position your codes as needed. Whether you’re adding kitemarks, 2D barcodes, serial numbers, or company names to a product, our solutions offer versatility. For instance, Domino’s D320i laser coder simplifies the production of unlimited lines of text in various orientations, fonts, and sizes, coding at speeds of up to 1,500 characters per second.

-

Maintenance-Free Operation

Domino introduces a range of service-free printers that are monitored and, if necessary, diagnosed through Domino Cloud. With data and event alerts, we ensure seamless printer functionality without the need for preventative maintenance or on-site servicing. Our support via Domino Cloud enhances production uptime.

-

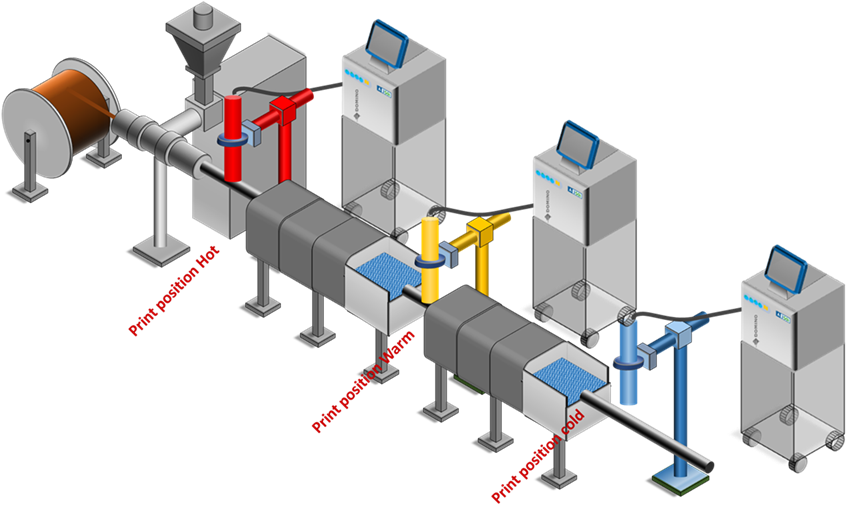

Simplified Installation – Adaptable to Any Production Environment

Exceptional technical specifications are only valuable if the coding technology fits seamlessly into your production environment. Domino addresses this with modular coders designed for easy installation and adaptability to any production setting. You have the flexibility to isolate both the touch screen and the printhead, placing them in the most convenient locations and seamlessly integrating them into your production line.

-

Create and Store Multiple Messages Locally on the Printer or Remotely with QuickDesign

Domino’s 10″ touch screen features an intuitive, smartphone-like interface, making it easy for operators, even those with limited experience, to create comprehensive messages on-site. For remote needs, we offer QuickDesign, Domino’s proprietary message design and coding automation software. This tool enables centralized design and storage of multiple messages, accessible by multiple units directly from the factory floor.

Questions?

-

Our Technology is Engineered for Durability

We deliver coding and marking technology built to withstand the challenges of demanding production environments. With IP66 electronics, our technology can endure on-line washdowns and the uncertainties of industrial settings.

-

Beyond the Sale…

Becoming a Codico customer goes beyond the initial purchase. You can benefit from our extended warranties, technical support, and aftermarket contracts. Our commitment to exceptional customer service is ingrained in our ethos. We believe in assisting each customer in effectively addressing their operational challenges and operating in a cost-efficient manner. Additionally, recognizing that the cost-saving efficiency of enterprise-grade coding and marking technology should be accessible to every business, we offer flexible leasing options along with direct sales. This way, even if your budget is not where you want it to be, you can still enjoy the advantages of utilizing innovative coding and marking technology through a manageable monthly fee!