How Does Variable Information Printing Function?

Variable data printing (VDP) empowers brands to deliver individualized and custom marketing messages to their customers, enhancing responses, providing brand security, and enabling product traceability. This is accomplished through the digital printing of variable information. Domino’s Digital Printing Solutions can handle everything from simple alphanumeric text and sequential numbering to various industry-standard machine-readable codes and high-resolution graphics, achieving printing speeds of up to 200 meters per minute. Amid the challenges posed by Covid, the demand for printing barcodes, QR codes, sequential numbers for serialization, track and trace, security features, brand protection, and anti-counterfeiting has become more crucial than ever. “COVID-19 has potentially accelerated the growth of e-commerce by five years,” notes Gary Peterson, Variable Data Solutions Manager for Domino North America. “With individuals working and staying at home, the demand for online purchases has significantly risen. Families, experiencing the convenience of e-commerce through easy online ordering and doorstep delivery, are incorporating it into their regular routines, a trend likely to persist even after lockdown restrictions ease. This surge in e-commerce has led to an immediate rise in the need for pre-printed barcode labels in logistics supply chains. Domino’s customers have witnessed a 40-50% surge in the demand for variable data label printing, and this upward trend is expected to continue,” Peterson adds.

“COVID-19 has potentially accelerated the growth of e-commerce by five years,” notes Gary Peterson, Variable Data Solutions Manager for Domino North America. “With individuals working and staying at home, the demand for online purchases has significantly risen. Families, experiencing the convenience of e-commerce through easy online ordering and doorstep delivery, are incorporating it into their regular routines, a trend likely to persist even after lockdown restrictions ease. This surge in e-commerce has led to an immediate rise in the need for pre-printed barcode labels in logistics supply chains. Domino’s customers have witnessed a 40-50% surge in the demand for variable data label printing, and this upward trend is expected to continue,” Peterson adds.

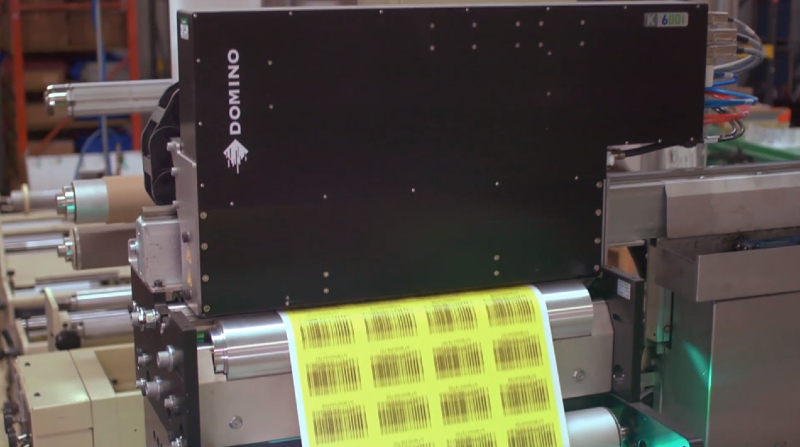

The Ideal Match: Domino K600i Digital UV Inkjet Printer

The Domino K600i is the ideal solution for this requirement. As a well-established digital UV inkjet printer with numerous installations worldwide, the K600i has demonstrated its effectiveness and reliability in variable data printing.

Offered in single-bar and dual-bar configurations with various widths, the Domino K600i print technology provides flexibility for label manufacturers to select the most suitable option for their requirements. The K600i seamlessly prints across the entire web width and can be integrated into flexo presses, rewinders, or finishing systems. The single-bar operates at a speed of 75m/min (246ft/min), and the dual-bar at speeds of up to 150m/min (492ft/min) with optimal density. This capability allows label manufacturers to capitalize on the Variable Data Printing (VDP) opportunity, ensuring profitable, efficient, and timely delivery to their brand owner customers.

- Monitor items across the logistics supply chain

- Tracing for food safety and product validation

- Consumer engagement and feedback initiatives

- Initiatives for loyalty, gaming, and marketing campaigns

- Security measures for brand safeguarding, diversion, and anti-counterfeiting

What Industries Benefit From Variable Data?

- Logistics and reverse logistics

- Food safety

- Tracking and tracing

- Promotional gaming and loyalty Radio

- Frequency Identification (RFID) integrations

- Security, anti-counterfeiting, and brand protection

Discover the Efficiency and Quality Enhancements Provided by Domino

Gary Peterson showcases the K600i dual bar, dual-speed digital UV inkjet printer. The remarkable features include the high speed and exceptional quality of the K600i dual bar system, aiding label manufacturers in increasing profitability while meeting customer requirements and surpassing expectations. View this video to explore how the productivity of this system can positively impact your business.

Peterson concludes, “The Domino K600i dual bar, dual speed unit will allow you to double your production speeds, reduce your hourly cost of operation, allow you to put other jobs on your press with the increased capacity you will have, and most importantly, it will allow you to make more profit on your existing assets.”

Peterson concludes, “The Domino K600i dual bar, dual speed unit will allow you to double your production speeds, reduce your hourly cost of operation, allow you to put other jobs on your press with the increased capacity you will have, and most importantly, it will allow you to make more profit on your existing assets.”